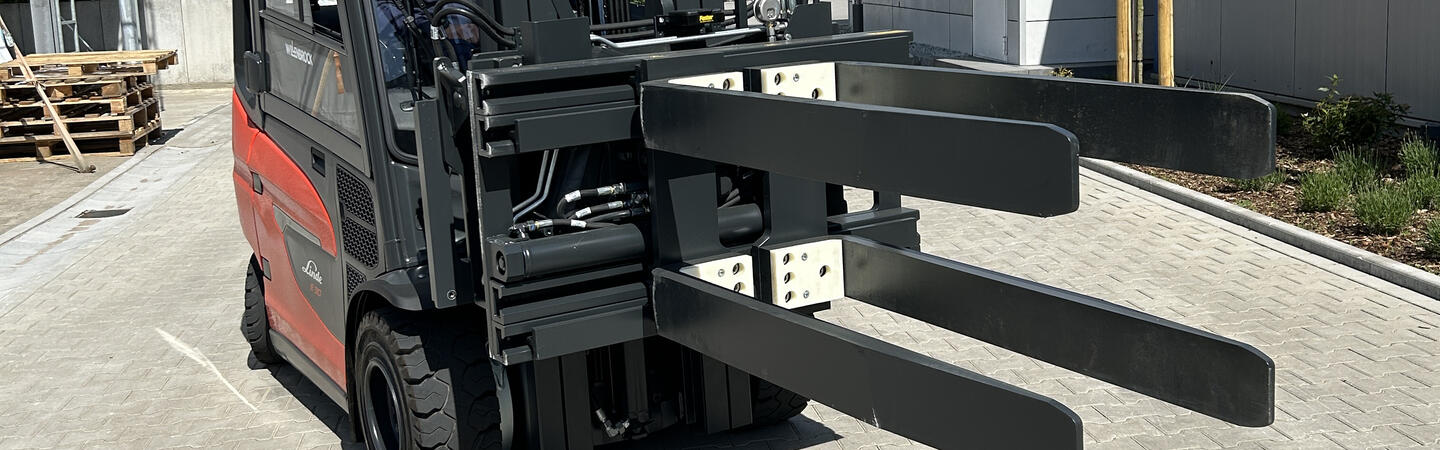

Flexible attachment change with the S 25 quick-coupling system from stabau

Efficiency, safety and flexibility play a crucial role in internal logistics. The WKT Group – Wernemann Kunststofftechnik in Geeste – has teamed up with stabau GmbH to find a solution that combines all three aspects. With the quick-change device from the S 25 series, the company can now change its attachments on forklift trucks independently, without tools and in no time at all.

The focus of the project was the customer's desire to be able to switch easily between a fork adjustment for standard pallet handling and a pallet turner. The S 25 quick-change device fully meets these requirements. Both mechanical and hydraulic changes are quick, safe and clean. A quick-change system allows the hydraulic connections to be connected and disconnected even under pressure and completely leak-free.

Greater safety and efficiency in material flow

The pallet turner supplied is used at WKT to turn plastic sheets – a task that was previously carried out manually. Using the stabau device eliminates the need for manual turning, which significantly increases work safety and reduces physical strain on employees. At the same time, processes become noticeably more efficient, as changing and turning the sheets can now be done automatically.

The model used is a standard pallet turner that is also suitable for handling pallet formats larger than the usual Euro pallets. This means that even large-format plastic sheets can be turned safely and in a controlled manner.

Well thought-out concept for flexible use

In addition to the quick-change device and the two attachments, an integrated parking device was also supplied, which enables the equipment to be parked safely when not in use. In combination with the forklift truck, the result is a complete system that is both technically and visually impressive.

‘The system offers our customer maximum flexibility and a high level of safety,’ explains sales representative Marcus Franke, who supervised the project. ‘The customer can now switch between different attachments independently and without additional effort – this saves time, reduces downtime and increases efficiency in daily operations.’

Conclusion

With the S 25 quick-change device and the matching combination of fork adjustment and pallet turner, stabau has created a customer-oriented solution that sustainably improves the material flow at the WKT Group. The independent, tool-free attachment change not only increases productivity but also employee safety – a practical example of efficient and flexible intralogistics solutions ‘Made in Germany’.